Laser Glass Cutting

Glass is widely used in fields, such as automotive, photovoltaic, screens, and home appliances due to its advantages including versatile shape, high transmissivity, and controllable cost. There is an increasing demand for glass processing with higher precision, faster speed, and greater flexibility (such as curve processing and irregular pattern processing) in these fields. However, the fragile nature of glass also poses a number of processing challenges, such as cracks, chips, and uneven edges. Here is how the laser can process glass materials and help glass processing improve production.

Laser Glass Cutting

Among traditional glass cutting methods, the more common ones are mechanical cutting, flame cutting, and waterjet cutting. The advantages and disadvantages of these three traditional glass cutting methods are as follows.

Mechanical Cutting

Advantages

1. Low cost and easy operation

2. Smooth incision Disadvantages

Disadvantages

1.Easy production of chips and micro-cracks, resulting in the reduced strength of the edge cut and CNC fine grinding of the edge cut needed

2.High cutting cost: the tool easy to wear and regular replacement needed

3.Low production: only straight lines cutting possible and difficult to cut shaped patterns

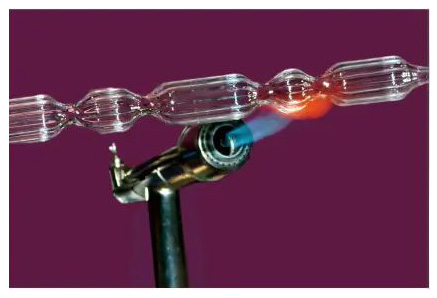

Flame Cutting

Advantages

1. Low cost and easy operation

Disadvantages

1.High thermal deformation, which prevents precision processing

2.Low speed and low efficiency, which prevent mass production

3.Fuel burning, which is not environmentally friendly

Waterjet Cutting

Advantages

1.CNC cutting of various complex patterns

2.Cold cutting: no thermal deformation or thermal effects

3.Smooth cutting: precise drilling, cutting, and molding processing finishes and no need for secondary processing

Disadvantages

1.High cost: use of large amounts of water and sand and high maintenance costs

2.High pollution and noise to the production environment

3.High impact force: not suitable for the processing of thin sheets

Traditional glass cutting has a great number of disadvantages, such as slow speed, high cost, limited processing, difficult positioning, and easy production of glass chips, cracks, and uneven edges. In addition, various post-processing steps (such as rinsing, grinding, and polishing) are needed to alleviate these problems, which inevitably increases additional production time and costs.

With the development of laser technology, laser glass cutting, non-contact processing, has been developing. Its working discipline is to focus the laser on the middle layer of glass and form the longitudinal and lateral burst point through thermal fusion, so as to change the molecular bond of the glass. In this way, additional impact force in the glass can be avoided without dust pollution and taper cutting. Moreover, uneven edges can be controlled within 10um. Laser glass cutting is easy to operate and environmentally friendly and avoids many disadvantages of traditional glass cutting.

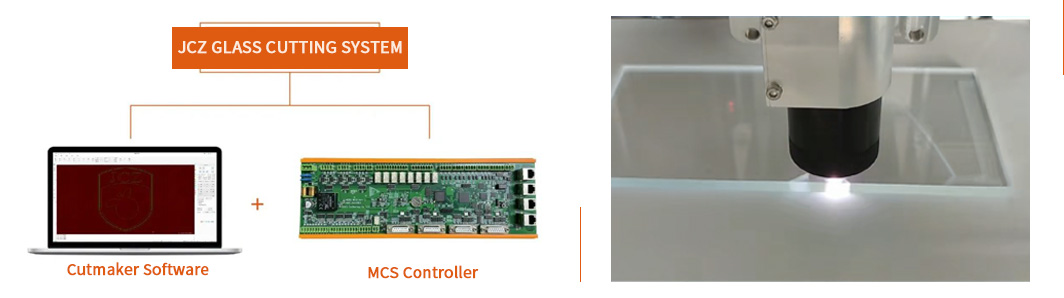

BJJCZ launches JCZ Glass Cutting System, abbreviated as P2000, for laser glass cutting. The system includes PSO function (point spacing accuracy of the arc up to ±0.2um at speed of 500mm/s), which can cut glass with high speed and high precision. By combining these advantages and the post-processing splitting, high-quality surface finishes can be achieved. The system has the advantages of high precision, no micro-cracks, no breakage, no chips, high edge resistance to breakage, and no need for secondary processing such as rinsing, grinding, and polishing, all of which significantly improves production and efficiency while reducing costs.

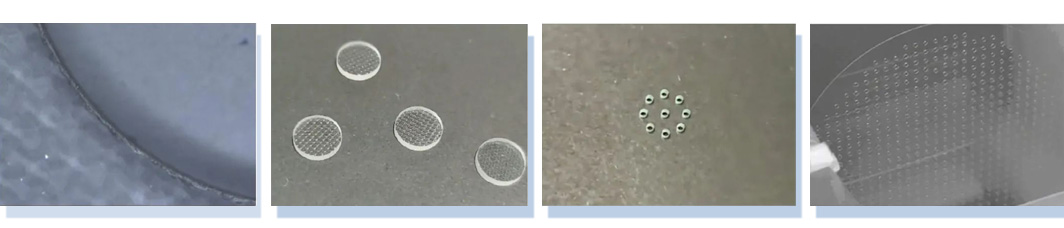

Processing Picture of Laser Glass Cutting

JCZ Glass Cutting System can be applied to process ultra-thin glass and complex shapes and patterns. It is commonly used in mobile phones, consumer electronics, 3C electronic products, insulating glass for automobiles, smart home screens, glassware, lenses, and other fields.

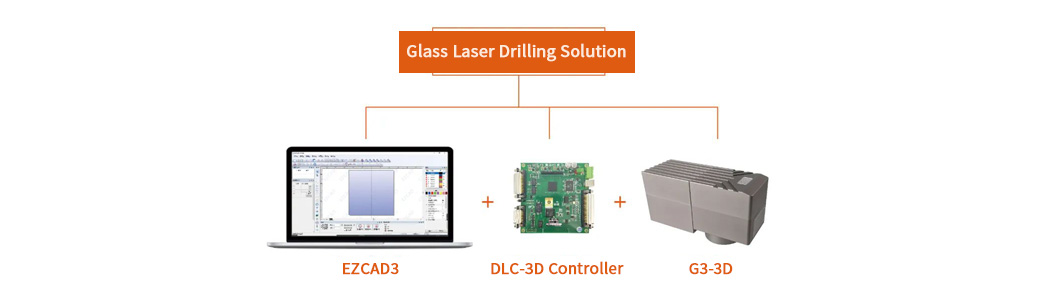

Laser Glass Drilling

Lasers can be applied not only in glass cutting, but also in the processing of through-holes with different apertures on glass, as well as micro-holes.

JCZ laser glass drilling solution can be applied to process various glass materials, such as quartz glass, curved glass, ultra-thin glass point by point, line by line, and layer by layer with high controllability. It has many advantages, including high flexibility, high speed, high precision, high stability, and the processing of various patterns, such as square holes, round holes, and listello holes.

JCZ laser glass drilling solution can be applied to photovoltaic glass, screens, medical glass, consumer electronics, and 3C electronics.

With the further development of glass manufacturing and the technology of glass processing and the emergence of lasers, new glass processing methods are available nowadays. Under the precise control of the laser control system, more precise and more efficient processing becomes a new choice.

Post time: May-06-2022