Ukusika iglasi yeLaser

Iglasi isetyenziswa kakhulu kwiamasimi, njengeiimoto, photovoltaic,izikrini, kunye nesixhobo sasekhayas ngenxa yayoiinzuzo kuqukaimilo eguquguqukayo,phezulutransmissiubomi, kunye neendleko ezilawulekayo.Kukho imfuno ekhulayo yokulungiswa kweglasi ngokuchaneka okuphezulu, isantya esikhawulezayo, kunye nokuguquguquka okukhulu (njengokusetyenzwa kwegophe kunye nokulungiswa kwepateni engaqhelekanga) kwezi nkalo.Nangona kunjalo, ubume beglasi obubuthathaka bubangela imiceli mngeni emininzi, njengokuqhekeka, iitshiphusi,kwayeimiphetho engalinganiyo.NantsiNjaniilaser caninkquboizinto zeglasi kunye nokunceda ukulungiswa kweglasi kuphuculweimveliso.

Ukusika iglasi yeLaser

Phakathi kweendlela zokusika iglasi yesiko, ezona zixhaphakileyo kukusika oomatshini, ukusika amadangatye,kwayeukusika ijethi yamanzi.Iinzuzo kunye nokungalunganga kwezi ndlela zintathu zokusika iglasizezi zilandelayo.

Ukusika oomatshini

Iingenelo

1. Iindleko eziphantsi kunye nokusebenza okulula

2. Ukusikwa okugudileyo

Iingxaki

1.Imveliso elula yeetshiphusi kunye neecracks ezincinci, ezikhokelela ekunciphiseni amandla okusikwa komphetho kunye ne-CNC ecoliweyo yokusila komphetho ofunekayo.

I-2.Ixabiso eliphezulu lokusika: isixhobo esilula ukusinxiba kunye nokutshintshwa rhoqo okufunekayo

I-3.Imveliso ephantsi: imigca ethe ngqo kuphela ukusika kunokwenzeka kwaye kunzima ukusika iipateni ezimile

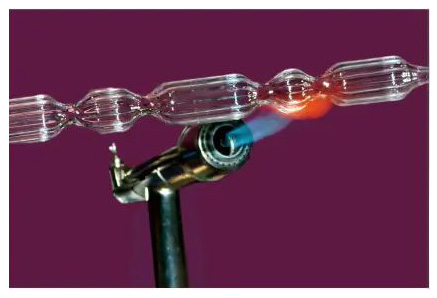

Ukusika iFlame

Iingenelo

1. Iindleko eziphantsi kunye nokusebenza okulula

Iingxaki

I-1.I-deformation ephezulu ye-thermal, evimbela ukucutshungulwa ngokuchanekileyo

I-2.Isantya esiphantsi kunye nokusebenza kakuhle okuphantsi, okuthintela ukuveliswa kobuninzi

I-3.Ukutshiswa kwamafutha, okungahambelani nokusingqongileyo

Ukusika i-Waterjet

Iingenelo

Ukusika kwe-1.CNC yeepateni ezahlukeneyo ezinzima

2.Ukusika okubandayo: akukho deformation ye-thermal okanye i-thermal effects

3. Ukusika okugudileyo: ukomba oluchanekileyo, ukusika, kunye nokubumba kugqityiwe kwaye akukho mfuneko yokusetyenzwa okwesibini

Iingxaki

I-1.Ixabiso eliphezulu: ukusetyenziswa kwamanzi amaninzi kunye nesanti kunye neendleko eziphezulu zokugcina

2.Ungcoliseko oluphezulu kunye nengxolo kwindawo yemveliso

I-3.Impembelelo ephezulu yamandla: ayifanelekanga ukulungiswa kwamaphepha amancinci

Ukusika iglasi yemveli inenani elikhulu lezinto ezingeloncedo, ezifana nesantya esicothayo, ixabiso eliphezulu, ukucutshungulwa okulinganiselweyo, indawo enzima, kunye nokuveliswa lula kweetshiphusi zeglasi, iintanda, kunye nemiphetho engalinganiyo.Ukongezelela, amanyathelo ahlukeneyo emva kokulungiswa (njengokuhlanjululwa, ukugaya, kunye nokupholisa) kuyafuneka ukuze kuncitshiswe ezi ngxaki, nto leyo eyongeza ixesha elongezelelweyo lokuvelisa kunye neendleko.

Ngophuhliso lwetekhnoloji ye-laser, ukusika iglasi ye-laser, ukusetyenzwa kwe-non-contact kuye kwaphuhliswa.Uqeqesho lwayo lokusebenza kukujolisa i-laser kumaleko aphakathi weglasi kwaye yenze indawo yokugqabhuka yelongitudinal kunye nesecaleni ngokudityaniswa kwe-thermal, ukuze utshintshe i-molecular bond yeglasi.Ngale ndlela, amandla empembelelo eyongezelelweyo kwiglasi inokuphetshwa ngaphandle kongcoliseko lothuli kunye nokusika i-taper.Ngaphezu koko, imiphetho engalinganiyo inokulawulwa ngaphakathi kwe-10um.Ukusika iglasi yeLaser kulula ukuyisebenzisa kwaye ihambelana nokusingqongileyo kwaye inqanda izinto ezininzi ezingalunganga zokusika iglasi yendabuko.

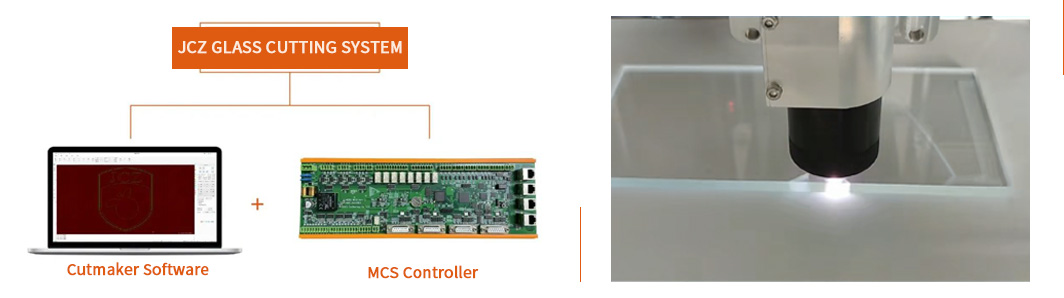

I-BJJCZ isungula i-JCZ Glass Cutting System, efinyeziweyo njenge-P2000, yokusika iglasi ye-laser.Inkqubo ibandakanya umsebenzi we-PSO (ukuchaneka kwesithuba se-arc ukuya kwi-± 0.2um ngesantya se-500mm / s), esinokusika iglasi ngesantya esiphezulu kunye nokuchaneka okuphezulu.Ngokudibanisa ezi nzuzo kunye nokwahlula emva kokulungiswa, ukugqitywa komgangatho ophezulu kunokufezekiswa.Inkqubo ineenzuzo zokuchaneka okuphezulu, akukho mikrolo, akukho kuqhekeka, akukho chips, ukuchasana komphetho ophakamileyo wokuqhekeka, kwaye akukho mfuneko yokusetyenzwa okwesibini njengokuhlanjululwa, ukugaya, kunye nokupholisha, konke oku kuphucula kakhulu imveliso kunye nokusebenza kakuhle ngelixa. ukunciphisa iindleko.

Ukucubungula Umfanekiso we-Laser Glass Cutting

I-JCZ ye-Glass Cutting System ingasetyenziselwa ukucubungula i-ultra-thin glass kunye nemilo enzima kunye neepatheni.Iqhele ukusetyenziswa kwiifowuni eziphathwayo, i-elektroniki yabathengi, iimveliso ze-elektroniki ze-3C, iglasi yokugquma iimoto, izikrini ezihlakaniphile zasekhaya, iiglasi, iilensi, kunye nezinye iindawo.

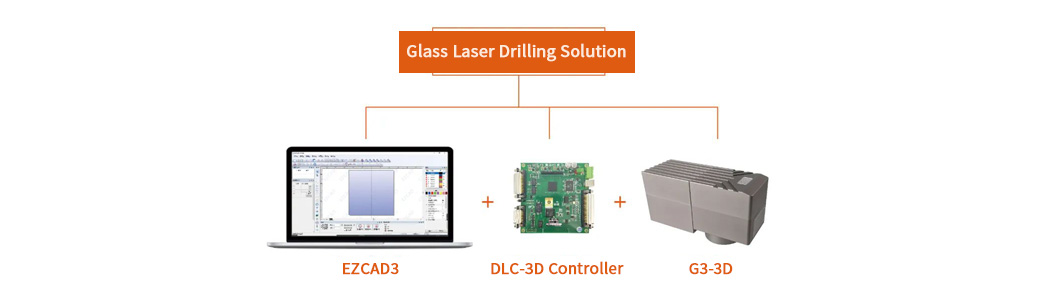

I-Laser Glass Drilling

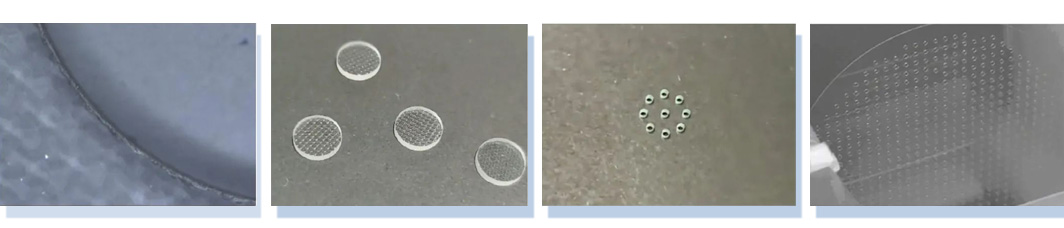

I-Lasers ingasetyenziswa kuphela kwi-glass cutting, kodwa nakwi-processing of through-mingxuma kunye ne-apertures eyahlukeneyo kwiglasi, kunye ne-micro-holes.

Isisombululo seglasi sokugrumba i-JCZ ye-laser ye-JCZ sinokusetyenziselwa ukucubungula izinto ezahlukeneyo zeglasi, ezifana neglasi ye-quartz, iglasi egobileyo, i-ultra-thin glass point point, umgca ngomgca, kunye ne-layer by layer with high controllability.Ineengenelo ezininzi, kubandakanywa nokuguquguquka okuphezulu, isantya esiphezulu, ukuchaneka okuphezulu, ukuzinza okuphezulu, kunye nokucutshungulwa kweepatheni ezahlukeneyo, njengemingxuma yesikwere, imingxuma engqukuva, kunye nemingxuma ye-listello.

Isisombululo se-JCZ laser sokomba iglasi singasetyenziswa kwiglasi ye-photovoltaic, izikrini, iglasi yezonyango, i-electronics yabathengi, kunye ne-3C elektroniki.

Ngophuhliso olongezelelweyo lokwenziwa kweglasi kunye nobuchwepheshe bokulungiswa kweglasi kunye nokuvela kweelaser, iindlela ezintsha zokulungisa iglasi zikhoyo namhlanje.Ngaphantsi kolawulo oluchanekileyo lwenkqubo yokulawula i-laser, ukuchaneka ngakumbi kunye nokusebenza ngokufanelekileyo kuba yinto entsha.

Ixesha lokuposa: May-06-2022