Laser Gilashin Yankan

Gilashi ana amfani dashi sosai a cikifilayen, kamarmota, photovoltaic,fuska, da kayan aikin gidas saboda taabũbuwan amfãni ciki har dam siffar,babbatransmissigaskiya, da farashi mai iya sarrafawa.Ana samun karuwar buƙatar sarrafa gilashin tare da daidaito mafi girma, saurin sauri, da sassauci mafi girma (kamar sarrafa lanƙwasa da sarrafa ƙirar da ba ta dace ba) a cikin waɗannan filayen.Koyaya, yanayin ƙarancin gilashin shima yana haifar da ƙalubalen sarrafawa da yawa, kamar fasa, guntu,kumam gefuna.Ananyayadaiya lasertsarikayan gilashin da taimakawa sarrafa gilashin ingantasamarwa.

Laser Gilashin Yankan

Daga cikin hanyoyin yankan gilasai na gargajiya, wadanda suka fi yawa sune yankan inji, yankan harshen wuta,kumayankan jet.Amfani da rashin amfanin waɗannan hanyoyin yankan gilashin gargajiya guda ukusune kamar haka.

Yankan Injini

Amfani

1. Low cost da sauki aiki

2. Lalacewar yanka mai laushi

Rashin amfani

1.Easy samar da kwakwalwan kwamfuta da micro-cracks, wanda ya haifar da raguwar ƙarfin da aka yanke da kuma CNC mai niƙa mai kyau na yanke da ake bukata.

2.High yankan farashi: kayan aiki mai sauƙi don sawa da sauyawa na yau da kullum da ake bukata

3.Low samar: kawai madaidaiciya Lines yankan yiwu da wuya a yanke siffa alamu

Yankan harshen wuta

Amfani

1. Low cost da sauki aiki

Rashin amfani

1.High thermal nakasawa, wanda ya hana daidaitaccen aiki

2.Low gudun da ƙananan inganci, wanda ke hana yawan samar da yawa

3.Fuel kona, wanda bai dace da muhalli ba

Yankan Waterjet

Amfani

1.CNC yanke na daban-daban hadaddun alamu

2.Cold yankan: babu thermal nakasawa ko thermal effects

3.Smooth yankan: daidai hakowa, yankan, da gyare-gyaren aiki gama kuma babu bukatar sakandare aiki

Rashin amfani

1.High kudin: yin amfani da ruwa mai yawa da yashi da kuma tsadar kulawa

2.High gurbatawa da kuma amo zuwa samar yanayi

3.High tasiri karfi: bai dace da aiki na bakin ciki zanen gado

Yanke gilashin gargajiya yana da adadi mai yawa na rashin amfani, kamar jinkirin saurin gudu, tsada mai tsada, iyakantaccen aiki, matsayi mai wahala, da sauƙin samar da kwakwalwan gilashi, fasa, da gefuna marasa daidaituwa.Bugu da kari, ana buƙatar matakai daban-daban bayan aiwatarwa (kamar kurkura, niƙa, da goge goge) don rage waɗannan matsalolin, wanda babu makawa ƙara ƙarin lokacin samarwa da farashi.

Tare da haɓaka fasahar Laser, yankan gilashin Laser, aiki mara lamba, yana tasowa.Horon aikin sa shine mayar da hankali kan laser akan tsakiyar gilashin da samar da wurin fashe a tsaye da na gefe ta hanyar haɗuwa da zafi, ta yadda za a canza haɗin kwayoyin halitta na gilashin.Ta wannan hanyar, ƙarin ƙarfin tasiri a cikin gilashin za a iya kauce masa ba tare da gurɓatar ƙura da yanke taper ba.Haka kuma, ana iya sarrafa gefuna marasa daidaituwa a cikin 10um.Yanke gilashin Laser yana da sauƙin aiki kuma yana da alaƙa da muhalli kuma yana guje wa yawancin rashin amfani na yankan gilashin gargajiya.

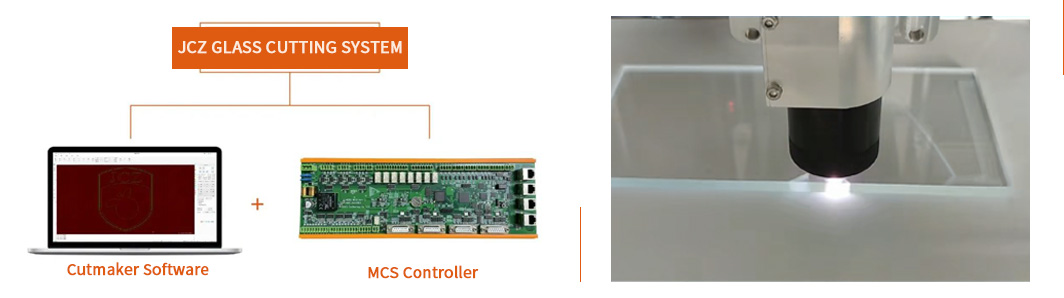

BJJCZ ta ƙaddamar da Tsarin Yankan Gilashin JCZ, wanda aka rage a matsayin P2000, don yankan gilashin Laser.Tsarin ya haɗa da aikin PSO (daidaicin tazarar maki na baka har zuwa ± 0.2um a saurin 500mm / s), wanda zai iya yanke gilashi tare da babban sauri da madaidaici.Ta hanyar haɗa waɗannan fa'idodin da rarrabuwa bayan aiwatarwa, ana iya samun kammalawar inganci mai inganci.Tsarin yana da fa'idodi na daidaitattun daidaito, babu ƙananan fasa, ba fasawa, babu guntu, babban juriya ga karyewa, kuma babu buƙatar sarrafa na biyu kamar kurkura, niƙa, da gogewa, waɗanda duk suna haɓaka samarwa da inganci yayin da suke haɓaka. rage farashin.

Sarrafa Hoton Laser Gilashin Yanke

Za a iya amfani da Tsarin Yankan Gilashin JCZ don aiwatar da gilashin bakin ciki da rikitattun siffofi da alamu.Ana amfani da shi sosai a cikin wayoyin hannu, kayan lantarki na mabukaci, samfuran lantarki na 3C, gilashin insulating don motoci, allon gida mai wayo, kayan gilashi, ruwan tabarau, da sauran filayen.

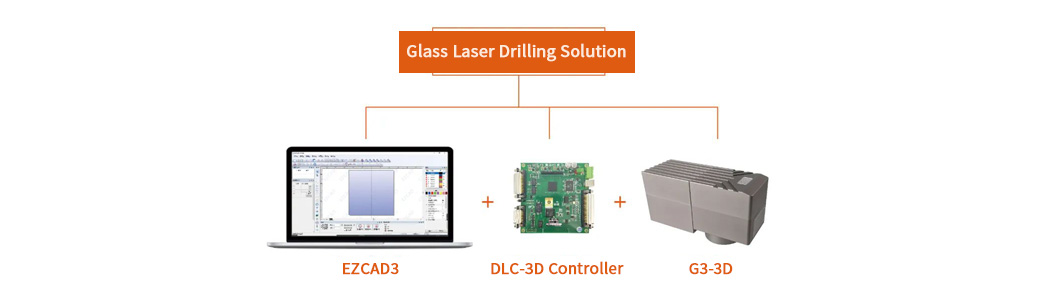

Gilashin Laser Drilling

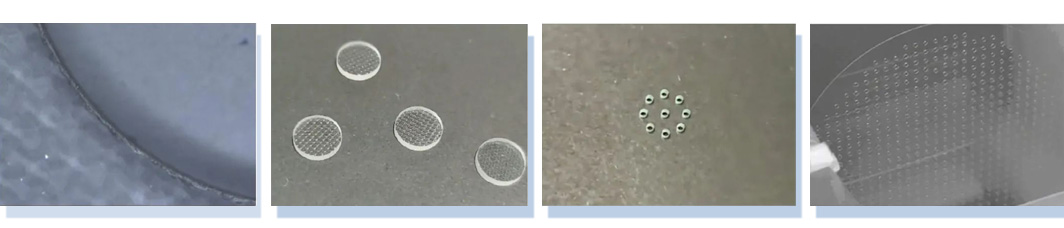

Ana iya amfani da Laser ba kawai a cikin yankan gilashi ba, har ma a cikin sarrafa ramuka tare da ramuka daban-daban akan gilashi, da ƙananan ramuka.

JCZ Laser gilashin hakowa bayani za a iya amfani da aiwatar da daban-daban gilashin kayan, kamar ma'adini gilashin, lankwasa gilashin, matsananci-bakin ciki gilashin batu, layi ta layi, da Layer ta Layer tare da high controllability.Yana da abũbuwan amfãni da yawa, ciki har da babban sassauci, babban gudu, babban madaidaici, babban kwanciyar hankali, da sarrafa nau'i daban-daban, kamar ramukan murabba'i, ramukan zagaye, da ramukan listello.

JCZ Laser gilashin hakowa bayani za a iya amfani da photovoltaic gilashin, fuska, likita gilashin, mabukaci Electronics, da 3C lantarki.

Tare da ci gaba da haɓaka masana'antar gilashi da fasaha na sarrafa gilashi da kuma fitowar laser, sababbin hanyoyin sarrafa gilashi suna samuwa a zamanin yau.A ƙarƙashin madaidaicin kulawar tsarin kula da Laser, mafi dacewa da ingantaccen aiki ya zama sabon zaɓi.

Lokacin aikawa: Mayu-06-2022