Laser iav txiav

iav yog dav siv nyob rau hauvteb, xws litsheb, photovoltaic,cov ntxaij vab tshaus, thiab khoom siv hauv tsevs vim nwsqhov zoo suav nrogntau yam zoo,siabkis tauvity, thiab tswj tau tus nqi.Muaj kev xav tau ntau ntxiv rau kev ua iav nrog kev ua kom zoo dua qub, nrawm dua, thiab hloov tau ntau dua (xws li kev ua nkhaus thiab cov qauv ua tsis zoo) hauv cov teb no.Txawm li cas los xij, qhov tsis yooj yim ntawm iav kuj ua rau muaj kev sib tw ua haujlwm, xws li tawg, chips,thiabntug tsis sib xws.Ntawm no yogua li castuslaser tautxheej txheemiav cov ntaub ntawv thiab pab iav ua kom zoo dua qubntau lawm.

Laser iav txiav

Ntawm cov tsoos iav txiav txoj kev, qhov ntau ntau yog cov neeg kho tshuab txiav, nplaim taws txiav,thiabwaterjet txiav.Qhov zoo thiab qhov tsis zoo ntawm peb txoj kev txiav iav tsoos noyog raws li nram no.

Mechanical Txiav

Qhov zoo

1. Tus nqi qis thiab ua haujlwm yooj yim

2. Smooth incision Disadvantages

Qhov tsis zoo

1.Easy zus tau tej cov chips thiab micro-cracks, uas ua rau txo lub zog ntawm ntug txiav thiab CNC zoo sib tsoo ntawm ntug txiav yuav tsum tau

2.High txiav nqi: lub cuab tam yooj yim rau hnav thiab hloov tsis tu ncua xav tau

3.Low ntau lawm: tsuas yog cov kab ncaj txiav tau thiab nyuaj rau txiav cov qauv zoo li tus

Nplaim Txiav

Qhov zoo

1. Tus nqi qis thiab ua haujlwm yooj yim

Qhov tsis zoo

1.High thermal deformation, uas tiv thaiv precision ua

2. Tsawg ceev thiab tsis tshua muaj kev ua haujlwm, uas tiv thaiv ntau lawm

3. Roj hlawv, uas tsis yog ib puag ncig tus phooj ywg

Waterjet Txiav

Qhov zoo

1.CNC txiav ntawm ntau yam qauv nyuaj

2.Cold cutting: tsis muaj thermal deformation lossis thermal cuam tshuam

3.Smooth txiav: meej drilling, txiav, thiab molding ua tiav thiab tsis xav tau kev ua haujlwm thib ob

Qhov tsis zoo

1.High nqi: siv ntau cov dej thiab xuab zeb thiab cov nqi kho mob siab

2.Cov kuab paug siab thiab suab nrov rau qhov chaw tsim khoom

3.High cuam tshuam quab yuam: tsis haum rau kev ua cov ntawv nyias

Kev txiav iav tsoos muaj ntau qhov tsis zoo, xws li qeeb qeeb, tus nqi siab, kev ua haujlwm tsawg, qhov chaw nyuaj, thiab yooj yim tsim cov iav chips, tawg, thiab cov npoo tsis sib xws.Tsis tas li ntawd, ntau cov kauj ruam tom qab ua tiav (xws li yaug, sib tsoo, thiab polishing) yog xav tau los daws cov teeb meem no, uas ua rau lub sijhawm ntau ntxiv thiab cov nqi ntxiv.

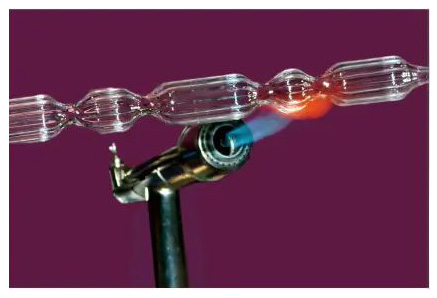

Nrog rau txoj kev loj hlob ntawm laser technology, laser iav txiav, tsis sib cuag ua, tau tsim.Nws txoj kev qhuab qhia ua haujlwm yog tsom rau lub laser ntawm nruab nrab txheej ntawm iav thiab tsim cov longitudinal thiab lateral tawg taw tes los ntawm thermal fusion, thiaj li hloov cov molecular daim ntawv cog lus ntawm iav.Nyob rau hauv txoj kev no, ntxiv kev cuam tshuam quab yuam nyob rau hauv lub khob yuav zam tau yam tsis muaj plua plav paug thiab taper txiav.Ntxiv mus, cov npoo tsis sib xws tuaj yeem tswj tau hauv 10um.Laser iav txiav yog ib qho yooj yim rau kev khiav lag luam thiab ib puag ncig tus phooj ywg thiab zam ntau yam tsis zoo ntawm tsoos iav txiav.

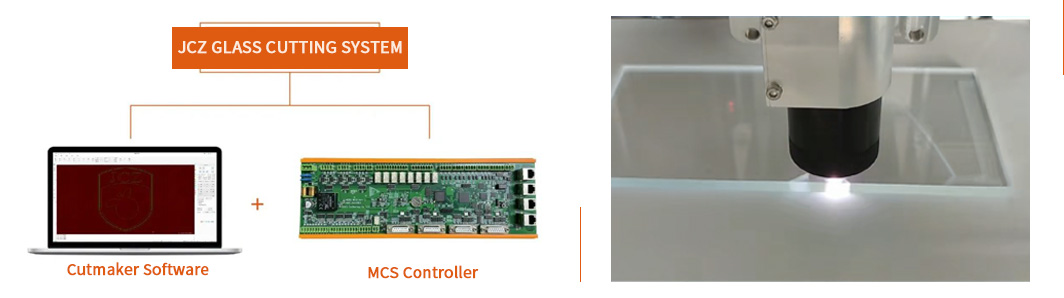

BJJCZ launches JCZ iav txiav System, abbreviated li P2000, rau laser iav txiav.Lub kaw lus suav nrog PSO muaj nuj nqi (cov ntsiab lus sib nrug qhov tseeb ntawm arc mus txog ± 0.2um ntawm qhov ceev ntawm 500mm / s), uas tuaj yeem txiav iav nrog kev kub ceev thiab siab precision.Los ntawm kev sib koom ua ke cov txiaj ntsig zoo thiab kev ua tiav tom qab kev sib cais, cov txheej txheem zoo tshaj plaws tuaj yeem ua tiav.Lub kaw lus muaj qhov zoo ntawm kev ua haujlwm siab, tsis muaj micro-cracks, tsis muaj kev tawg, tsis muaj chips, siab siab tiv thaiv kev tawg, thiab tsis xav tau kev ua haujlwm thib ob xws li yaug, sib tsoo, thiab polishing, tag nrho cov kev txhim kho ntau lawm thiab kev ua haujlwm zoo thaum txo cov nqi.

Daim duab ntawm Laser iav txiav

JCZ iav Txiav System tuaj yeem siv los ua cov iav ultra-nyias thiab cov duab thiab cov qauv.Nws yog feem ntau siv hauv xov tooj ntawm tes, khoom siv hluav taws xob, 3C cov khoom siv hluav taws xob, insulating iav rau tsheb, cov ntxaij vab tshaus hauv tsev, iav, lo ntsiab muag, thiab lwm yam.

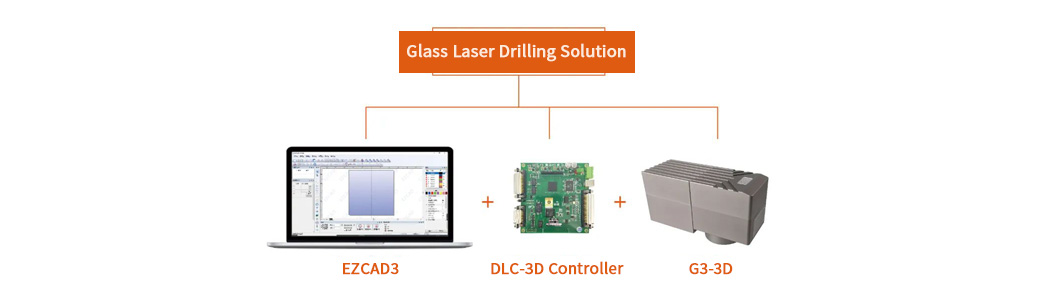

Laser iav Drilling

Lasers tuaj yeem siv tsis tau tsuas yog hauv cov iav txiav, tab sis kuj tseem nyob rau hauv kev ua tiav ntawm qhov sib txawv ntawm cov iav, nrog rau micro-qhov.

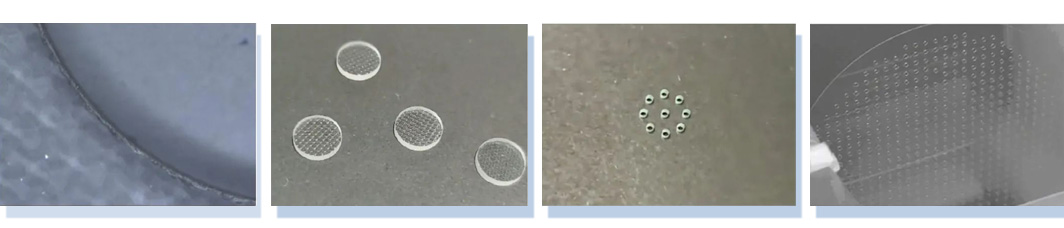

JCZ laser iav drilling tov tuaj yeem siv los ua cov khoom siv iav ntau yam, xws li quartz iav, nkhaus iav, ultra-thin iav taw tes los ntawm taw tes, kab los ntawm kab, thiab txheej los ntawm txheej nrog siab controllability.Nws muaj ntau yam zoo, suav nrog kev hloov pauv siab, kev kub ceev, siab precision, siab ruaj khov, thiab kev ua haujlwm ntawm ntau yam qauv, xws li square qhov, round qhov, thiab listello qhov.

JCZ laser iav drilling tov tuaj yeem siv rau cov iav photovoltaic, cov ntxaij vab tshaus, iav kho mob, khoom siv hluav taws xob, thiab 3C electronics.

Nrog rau kev txhim kho ntxiv ntawm iav tsim thiab thev naus laus zis ntawm kev ua iav thiab qhov tshwm sim ntawm lasers, cov txheej txheem tshiab iav yog muaj tam sim no.Raws li kev tswj hwm ntawm lub laser tswj qhov system, kev ua kom zoo dua qub thiab ua tau zoo dua los ua qhov kev xaiv tshiab.

Post lub sij hawm: May-06-2022