I-Laser Glass Cutting

Ingilazi isetshenziswa kabanzi kuamasimu, njengeimoto, i-photovoltaic,izikrini, nezinto zikagesi zasekhayas ngenxa yayoizinzuzo kuhlanganiseumumo ohlukahlukene,phezulutransmissiamandla, kanye nezindleko ezilawulekayo.Kunesidingo esikhulayo sokucutshungulwa kwengilazi ngokunemba okuphezulu, isivinini esisheshayo, kanye nokuguquguquka okukhulu (njengokucubungula ijika nokucutshungulwa kwephethini okungajwayelekile) kule mikhakha.Kodwa-ke, isimo esintekenteke sengilazi sibuye sibe nezinselelo eziningi zokucubungula, njengokuqhekeka, ama-chips,futhiimiphetho engalingani.NakhuKanjaniii-laser caninquboizinto zengilazi nokusiza ukucubungula ingilazi kuthuthukeukukhiqiza.

I-Laser Glass Cutting

Phakathi kwezindlela zokusika ingilazi zendabuko, ezivame kakhulu ukusika ngomshini, ukusika amalangabi,futhiukusika i-waterjet.Izinzuzo kanye nokubi zalezi zindlela ezintathu zendabuko zokusika ingilazizimi kanje.

Ukusika Ngomshini

Izinzuzo

1. Izindleko eziphansi nokusebenza okulula

2. Ukusika ubushelelezi

Ukubi

1. Ukukhiqizwa okulula kwama-chips nama-micro-cracks, okuholela ekunciphiseni amandla okusikwa konqenqemeni kanye nokugaya okuhle kwe-CNC kokusikwa konqenqemeni okudingekayo.

I-2.Izindleko zokusika eziphezulu: ithuluzi eligqokeka kalula nokushintshwa okujwayelekile okudingekayo

I-3.Ukukhiqizwa okuphansi: imigqa eqondile kuphela esika kungenzeka futhi kunzima ukusika amaphethini amise

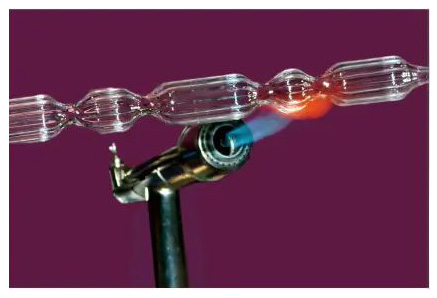

I-Flame Cutting

Izinzuzo

1. Izindleko eziphansi nokusebenza okulula

Ukubi

I-1.Ukuguqulwa kwe-thermal ephezulu, okuvimbela ukucubungula ukunemba

I-2.Ijubane eliphansi nokusebenza kahle okuphansi, okuvimbela ukukhiqizwa okukhulu

3.Ukushiswa kwamafutha, okungahambisani nemvelo

I-Waterjet Cutting

Izinzuzo

Ukusika kwe-1.CNC kwamaphethini ahlukahlukene ayinkimbinkimbi

2.Ukusika okubandayo: akukho deformation yokushisa noma imiphumela yokushisa

3.Ukusika okubushelelezi: ukubhola okunembile, ukusika, nokubumba kuyaqeda futhi asikho isidingo sokucutshungulwa kwesibili

Ukubi

I-1.Izindleko eziphezulu: ukusetshenziswa kwamanzi amaningi nesihlabathi kanye nezindleko eziphezulu zokulondoloza

2.Ukungcola okuphezulu kanye nomsindo endaweni yokukhiqiza

3.Amandla omthelela aphezulu: awafanele ukucubungula amashidi amancane

Ukusika ingilazi evamile kunenani elikhulu lokubi, njengesivinini esinensayo, izindleko eziphezulu, ukucubungula okulinganiselwe, ukuma okunzima, nokukhiqizwa okulula kwamashiphu engilazi, ukuqhekeka, nemiphetho engalingani.Ukwengeza, izinyathelo ezihlukahlukene zangemuva kokucubungula (njengokuhlambulula, ukugaya, nokupholisha) ziyadingeka ukuze kuncishiswe lezi zinkinga, okwandisa nakanjani isikhathi sokukhiqiza nezindleko ezengeziwe.

Ngokuthuthuka kobuchwepheshe be-laser, ukusika ingilazi ye-laser, ukucutshungulwa okungathintana naye, bekuthuthuka.Isiyalo sayo sokusebenza siwukugxilisa i-laser ongqimbeni olumaphakathi lwengilazi bese kwakha indawo yokuqhuma kwe-longitudinal ne-lateral ngokusebenzisa ukuhlanganisa okushisayo, ukuze kuguqulwe ibhondi yamangqamuzana engilazi.Ngale ndlela, amandla engeziwe omthelela engilazini angagwenywa ngaphandle kokungcoliswa kothuli nokusika kwe-taper.Ngaphezu kwalokho, imiphetho engalingani ingalawulwa ngaphakathi kwe-10um.Ukusika ingilazi ye-laser kulula ukuyisebenzisa futhi kuyahambisana nemvelo futhi kugwema ukubi okuningi kokusika ingilazi yendabuko.

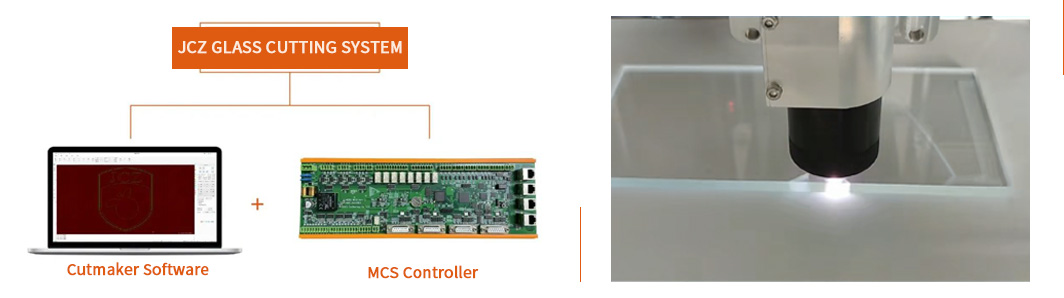

I-BJJCZ yethula i-JCZ Glass Cutting System, efushanisiwe njenge-P2000, yokusika ingilazi ye-laser.Uhlelo luhlanganisa umsebenzi we-PSO (ukunemba kwesikhala samaphuzu se-arc kuze kufike ku-± 0.2um ngesivinini se-500mm / s), esingasika ingilazi ngesivinini esikhulu nokunemba okuphezulu.Ngokuhlanganisa lezi zinzuzo kanye nokuhlukaniswa ngemuva kokucubungula, ukuqedwa kwekhwalithi ephezulu kungafinyelelwa.Uhlelo lunezinzuzo zokunemba okuphezulu, akukho mifantu emincane, akukho ukuphuka, akukho chips, ukumelana okuphezulu konqenqema ukuphuka, futhi asikho isidingo sokucutshungulwa kwesibili njengokuhlambulula, ukugaya, nokupholisha, konke okuthuthukisa kakhulu ukukhiqizwa nokusebenza kahle ngenkathi ukunciphisa izindleko.

Icubungula Isithombe Se-Laser Glass Cutting

I-JCZ Glass Cutting System ingasetshenziswa ukucubungula ingilazi ezacile kakhulu kanye namajamo namaphethini ayinkimbinkimbi.Ivamise ukusetshenziswa komakhalekhukhwini, izinto zikagesi zabathengi, imikhiqizo kagesi engu-3C, ingilazi evikelayo yezimoto, izikrini zasekhaya ezihlakaniphile, i-glassware, amalensi, nezinye izinkambu.

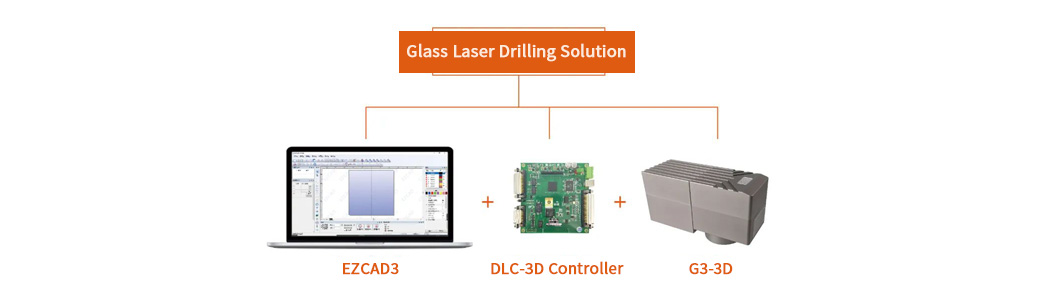

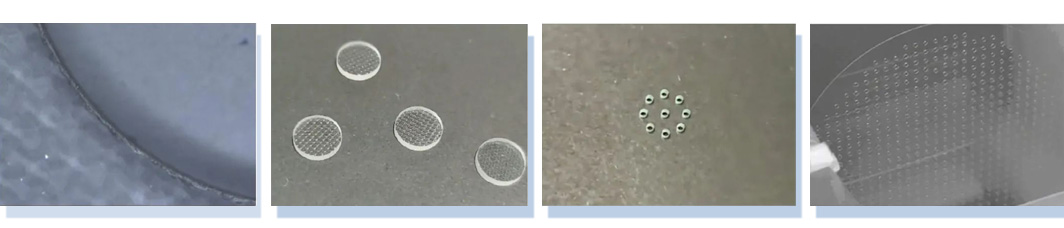

I-Laser Glass Drilling

Ama-Lasers angasetshenziswa hhayi kuphela ekusikeni ingilazi, kodwa nasekucubunguleni izimbobo ezinezikhala ezihlukene engilazini, kanye nezimbobo ezincane.

Isixazululo sokumba ingilazi ye-JCZ laser singasetshenziswa ukucubungula izinto ezihlukahlukene zengilazi, njengengilazi ye-quartz, ingilazi egobile, i-ultra-thin glass point by point, umugqa ngomugqa, kanye nongqimba ngongqimba olunokulawulwa okuphezulu.Inezinzuzo eziningi, okuhlanganisa ukuguquguquka okuphezulu, isivinini esikhulu, ukunemba okuphezulu, ukuzinza okuphezulu, nokucutshungulwa kwamaphethini ahlukahlukene, njengezimbobo eziyisikwele, izimbobo eziyindilinga, nezimbobo ze-listello.

Isixazululo sokumba ingilazi ye-JCZ laser singasetshenziswa engilazini ye-photovoltaic, izikrini, ingilazi yezokwelapha, i-electronics yabathengi, kanye ne-electronics ye-3C.

Ngokuthuthuka okuqhubekayo kokukhiqizwa kwengilazi kanye nobuchwepheshe bokucubungula ingilazi kanye nokuvela kwama-lasers, izindlela ezintsha zokucubungula ingilazi ziyatholakala namuhla.Ngaphansi kokulawula okunembile kwesistimu yokulawula i-laser, ukucutshungulwa okunembe kakhudlwana nokusebenza kahle kuba ukukhetha okusha.

Isikhathi sokuthumela: May-06-2022