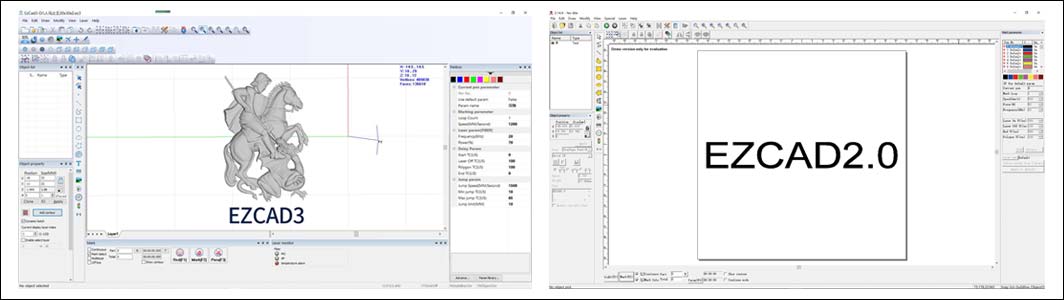

Since its establishment in 2004, JCZ has been focusing on the development of beam transmission and control system solutions. The self-developed Ezcad2 software, which can realize the functions of plane graphic marking, bitmap/vector graphic processing, serial number (automatic number skipping) processing, rotary axis processing, multi-document processing, etc., is widely praised by users for its powerful functions, easy operation and high stability, and is now widely used in major laser processing industries. With the progress of society, innovation never stops. According to the needs of users, JCZ has developed Ezcad3 software based on the continuous optimization of Ezcad2. Ezcad3 has been greatly improved in terms of function and performance. Ezcad3 supports all the functions of Ezcad2, but also adds TCP remote control function, multi-layer processing, multi-layer offline, 3D model processing, dual-axis flight, dynamic filling and other A variety of functions. The software UI follows the style of Ezcad2, and the software background can be customized to facilitate quick start-up operation.

3D surface processing supports DXF, STL and other 3D file formats, automatic adjustment of laser focus on 3D curved objects, without multiple assembly focus, no distortion, with greater processing range and finer light effect.

Electronic components, electrical appliances, auto and motorcycle parts, precision hardware, gifts and accessories, medical equipment, glasses and clocks, instruments and meters, sanitary ware, stainless steel kitchenware supplies, etc.

3D laser deep engraving processing is the use of laser on the mold (metal or wood) to carve out the designed texture style. The processing accuracy is high and tiny texture structure can be processed, making the processed relief more vivid and realistic. The processing efficiency is fast, which can significantly shorten the production cycle.

Wood carving accessories, ivory carving, jade carving, stone monument carving, stone screen carving, antique home furnishings, wall hangings, lighting accessories, wooden doors, door rings, jewelry, hang tags, commemorative coins, etc.

Large-format flying marking with front-focus mode is widely used in the field of high-precision, automated marking, and is suitable for large workloads, difficult positioning of material supply, diverse and complex workpieces, etc.

Garment and textile industry, elevator panels, mirror processing, leather fabrics, metal nameplates, stickers, hot stamping films, engraved films, bamboo sketches, sanitary products, etc.

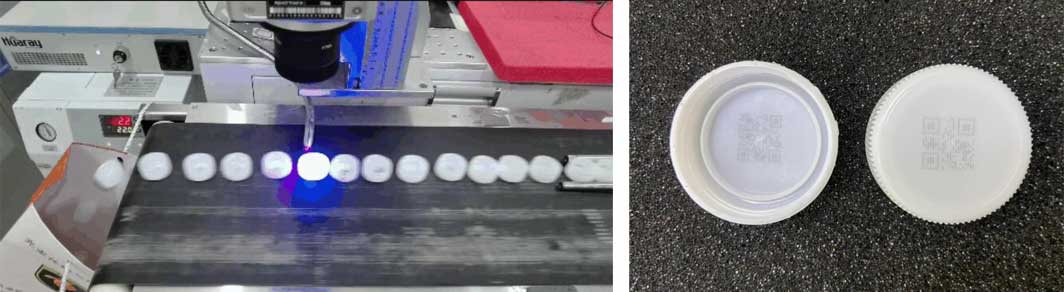

Fast 2D code processing means processing the 2D code object on the product with extremely high efficiency. The processing time of a single 2D code (10*10mm) is within 20ms, and the 2D code recognition rate is up to 99.9%. It greatly improves production efficiency and can significantly shorten the production cycle.

Pipeline processing for tobacco, wine, food, beverage packaging, medicine, home appliances, kitchenware and other industries.

Support QCW laser, real-time display laser status, can be adjusted according to different laser parameters by the software to achieve the current, pulse frequency, duty cycle and other parameters. Support high-power lasers to meet the needs of high-quality laser cutting and welding.

Consumer electronics, ceramic punching, lithium batteries, medical equipment, ships, manufacturing of automobiles and parts, optical communication devices, IT, precision parts, etc.

Post time: Jan-06-2022