EZCAD3, an advanced software solution, plays a pivotal role in revolutionizing industrial manufacturing processes by offering a diverse set of applications. This analysis explores the extensive applications of EZCAD3 within the realm of industrial manufacturing:

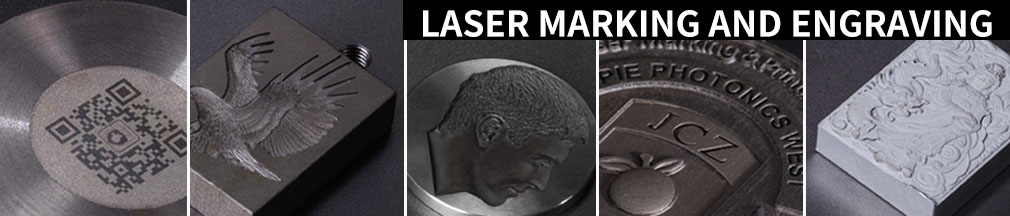

Laser Marking and Engraving:

-EZCAD3 continues to excel in laser marking and engraving applications, providing manufacturers with advanced tools for creating intricate and precise markings on various materials. This capability is essential for product identification, branding, and traceability.

Dynamic Marking and Serialization:

EZCAD3 introduces dynamic marking capabilities, allowing manufacturers to implement serializations, barcodes, and QR codes dynamically. This facilitates unique identification and traceability of each product, contributing to quality control and regulatory compliance.

2D and 3D Marking:

With enhanced features, EZCAD3 supports both 2D and 3D marking applications. This is particularly valuable in industries where complex and multi-dimensional markings are required for detailed product information and customization.

Vision Integration:

EZCAD3 integrates seamlessly with vision systems, enabling precise alignment and positioning of laser markings. This ensures accuracy and consistency, especially in applications where exact placement is critical, such as electronics manufacturing.

Multi-Axis Control:

Industrial manufacturing processes often involve intricate components. EZCAD3's multi-axis control feature allows for precise laser movements on multiple axes, enhancing the software's applicability in tasks requiring intricate and complex markings.

Advanced Material Compatibility:

EZCAD3 offers improved compatibility with a wide range of materials, including metals, plastics, ceramics, and composites. This versatility makes it suitable for diverse industrial applications where materials may vary.

Real-time Monitoring and Reporting:

EZCAD3 introduces real-time monitoring and reporting features, providing manufacturers with insights into the marking process. This enhances quality control by identifying and addressing issues promptly, reducing production downtime.

Augmented Reality (AR) Integration:

In an era of Industry 4.0, EZCAD3 supports integration with augmented reality technologies. This allows for enhanced visualization and simulation of laser marking processes, aiding in design validation and process optimization.

Enhanced User Interface and Workflow Optimization:

The user interface of EZCAD3 is designed for enhanced user experience and workflow optimization. Intuitive controls and streamlined processes contribute to improved efficiency and reduced learning curves for operators.

In conclusion, EZCAD3 emerges as a cutting-edge solution for industrial manufacturing, offering advanced features that go beyond traditional laser marking applications. Its dynamic marking, vision integration, and compatibility with Industry 4.0 technologies position it as a key player in modern manufacturing environments, fostering efficiency, precision, and adaptability.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Post time: Dec-27-2023