Laser yekuchenesa tekinoroji inoshandisa yakamanikana pulse hupamhi, yakakwirira simba density lasers pamusoro pechinhu chinofanira kucheneswa.Kuburikidza nemhedzisiro yakasanganiswa yekukurumidza kudengenyeka, vaporization, kuora, uye plasma peeling, zvinosvibisa, marara emarara, kana machira ari pamusoro anobuda nekukurumidza uye kuvharika, achiwana kuchenesa pamusoro.

Laser kucheneswa kunopa zvakanakira senge kusabatana, kushamwaridzana kwezvakatipoteredza, kunyatsoita, uye hapana kukuvadzwa kune substrate, zvichiita kuti ishande munzvimbo dzakasiyana siyana.

Laser Kuchenesa

Green uye Inoshanda

Indasitiri yematayi, indasitiri yesimba idzva, uye indasitiri yemichina yekuvaka, pakati pezvimwe, inoshandisa zvakanyanya laser kuchenesa.Munguva ye "mbiri mbiri kabhoni" zvibodzwa, laser yekuchenesa iri kubuda semhinduro nyowani mumusika wechinyakare wekuchenesa nekuda kwekushanda kwayo kwakanyanya, kunyatso kudzora, uye hunhu hune hushamwari.

Pfungwa yekuchenesa Laser:

Kucheneswa kweLaser kunosanganisira kutarisisa matanda e-laser pamusoro pezvinhu kuti akurumidze kunyungudika kana kubvisa zvinosvibisa pamusoro, kuwana zvinhu zvekuchenesa.Kuenzaniswa nemhando dzakasiyana dzechinyakare dzemuviri kana kemikari yekuchenesa nzira, laser yekuchenesa inoratidzirwa nekusaonana, hapana chinodyiwa, hapana kusvibiswa, yakakwira chaiyo, uye kushoma kana kusakuvadzwa, zvichiita kuti ive sarudzo yakanaka kune chizvarwa chitsva cheindasitiri yekuchenesa tekinoroji.

Nheyo yekuchenesa Laser:

Nheyo yekuchenesa laser yakaoma uye inogona kusanganisira zvese zvemuviri nemakemikari maitiro.Muzviitiko zvakawanda, maitiro emuviri anotonga, achiperekedzwa nechikamu chemakemikari maitiro.Iwo makuru maitiro anogona kuiswa mumhando nhatu: vaporization process, shock process, uye oscillation process.

Gasification process:

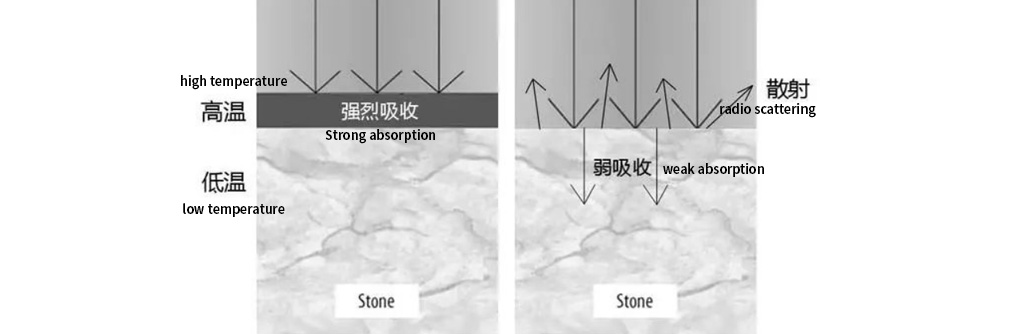

Kana high-energy laser irradiation ichiiswa pamusoro pechinhu, iyo yepamusoro inotora simba relaser uye inoshandura kuita simba remukati, zvichiita kuti kupisa kwepasi kuwedzere nekukurumidza.Uku kukwira kwetembiricha kunosvika kana kudarika tembiricha ye vaporization yechinhu, zvichiita kuti zvinosvibisa zvibvire kubva pane chinhu chiri muchimiro chemhute.Kusarudza vaporization kunowanzoitika kana mwero wekunyudzwa kwezvinosvibisa kune laser wakakwira zvakanyanya kupfuura weiyo substrate.Muenzaniso wekushandisa ndeyekucheneswa kwetsvina pamatombo.Sezvinoratidzwa mumufananidzo uri pasi apa, zvinosvibisa pamusoro pedombo zvinotora laser uye zvinokurumidza kunyungudutswa.Kana izvo zvinosvibisa zvabviswa zvachose, uye laser inovhenekera pamusoro pedombo, kunyura kunoderera, uye yakawanda laser simba inoparadzirwa nedombo pamusoro.Nekuda kweizvozvo, kune kushoma shanduko mukupisa kwenzvimbo yedombo, nekudaro ichidzivirira kubva mukukuvadzwa.

Maitiro akajairika anosanganisira kuita kwemakemikari anoitika kana kuchenesa organic zvinosvibisa neultraviolet wavelength lasers, maitiro anozivikanwa selaser ablation.Ultraviolet lasers ine mapfupi wavelengths uye yakakwirira photon simba.Semuenzaniso, KrF excimer laser ine wavelength ye 248 nm ine photon simba re 5 eV, iyo inokwira ka40 kupfuura iyo CO2 laser photons (0.12 eV).Yakadaro yakakwira photon simba inokwana kutyora mamolecular bond mune organic zvinhu, zvichiita kuti CC, CH, CO, nezvimwewo, zvisungo zviri muorganic zvinosvibisa zvityoke pakubata iyo photon simba relaser, zvichiita kuti pyrolytic gasification uye kubviswa kubva pamusoro.

Shock process muLaser Cleaning:

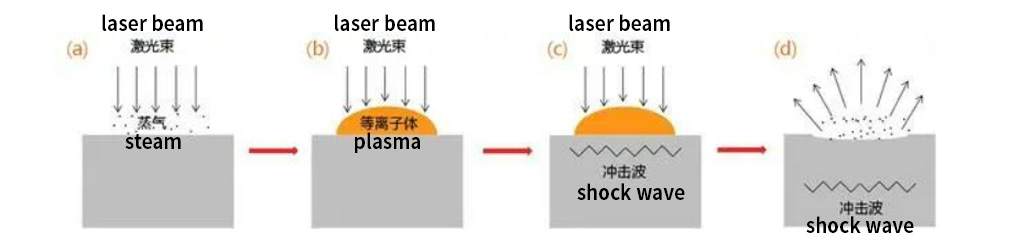

Iyo yekuvhundutsa maitiro mukuchenesa laser inosanganisira akateedzana maitiro anoitika panguva yekudyidzana pakati pelaser uye zvinhu, zvichikonzera kuvhunduka kwemafungu anokanganisa pamusoro pechinhu.Pasi pesimba remafungu anovhundutsa aya, zvinosvibisa pamusoro zvinoputsika kuita huruva kana zvidimbu, zvichisvuura kubva pamusoro.Nzira dzinokonzera aya mafungu ekuvhundutsa dzakasiyana-siyana, kusanganisira plasma, mhute, uye kukurumidza kuwedzera kwemafuta uye kudonhedza zviitiko.

Tichitora mafungu ekuvhundutsa eplasma semuenzaniso, tinogona kunzwisisa muchidimbu nzira yekuvhunduka mukuchenesa laser inobvisa zvinosvibisa pamusoro.Nekushandiswa kweyekupedzisira-pfupi pulse hupamhi (ns) uye yekupedzisira-yepamusoro peak simba (107- 1010 W/cm2) lasers, tembiricha yepasi inogona kukwira zvakanyanya kusvika kune vaporization tembiricha kunyangwe kunyudzwa kwepasi kwelaser kusina simba.Uku kukurumidza kuwedzera tembiricha kunoumba mhute pamusoro pechinhu chacho, sezvinoratidzwa mumufananidzo (a).Tembiricha yemhute inogona kusvika 104 - 105 K, inokwana kuita ionize iyo mhute pachayo kana mhepo yakatenderedza, ichigadzira plasma.Iyo plasma inovharira laser kuti isasvike pamusoro pezvinhu, pamwe inomisa pamusoro vaporization.Nekudaro, iyo plasma inoramba ichitora laser simba, ichiwedzera kuwedzera tembiricha yayo uye kugadzira nzvimbo yenzvimbo yekupisa kwakanyanya uye kudzvanywa.Izvi zvinoburitsa kanguva kadiki-diki ke1-100 kbar pamusoro pezvinhu uye zvishoma nezvishoma zvichiendesa mukati, sezvinoratidzwa mumifananidzo (b) uye (c).Pasi pesimba reshock wave, zvinosvibisa zvepasi zvinotsemuka kuita guruva diki, zvidimbu, kana zvidimbu.Kana iyo laser ichibva panzvimbo yakasvibiswa, plasma inonyangarika nekukurumidza, ichigadzira kudzvanywa kwakashata kwenzvimbo, uye zvimedu kana zvidimbu zvezvinosvibisa zvinobviswa kubva pamusoro, sezvakaratidzwa mumufananidzo (d).

Oscillation Maitiro muLaser Yekuchenesa:

Mune oscillation process yekuchenesa laser, zvese kupisa uye kutonhora kwezvinhu zvinoitika nekukurumidza zvakanyanya pasi pesimba repfupi-pulse lasers.Nekuda kwekusiyana kwekupisa kwekuwedzera kwemafuta emhando dzakasiyana-siyana, iyo inosvibisa pamusoro uye iyo substrate inopinda yakakwirira-frequency yekuwedzera kupisa uye kudonhedza kweakasiyana madhigirii kana akafumurwa pfupi-pulse laser irradiation.Izvi zvinotungamira kune oscillatory mhedzisiro inokonzeresa kuti zvinosvibisa zvibviswe kubva pane zvinhu.

Munguva iyi yekupepeta, kunyungudika kwezvinhu kungasaitika, uye plasma haisati yaumbwa.Pane kudaro, iyo nzira inotsamira pamasimba eshear anogadzirwa pakusangana pakati pekusvibisa uye substrate pasi pechiito che oscillatory, chinoputsa chisungo pakati pavo.Zvidzidzo zvakaratidza kuti kuwedzera zvishoma kona yechiitiko chelaser kunogona kukwidziridza kusangana pakati pelaser, iyo yakasvibiswa inosvibisa, uye chimiro cheiyo substrate.Iyi nzira inodzikisira chikumbaridzo chekuchenesa laser, ichiita kuti oscillatory mhedzisiro iwedzere kutaurwa uye kugadzirisa kuchenesa.Nekudaro, iyo kona yezviitiko haifanirwe kunge yakakura kwazvo, sezvo yakakwira kona inogona kuderedza simba density ichiita pamusoro pezvinhu, nekudaro ichideredza kugona kwekuchenesa kwelaser.

Industrial Applications yeLaser Cleaning:

1: Mold Industry

Laser yekuchenesa inogonesa isina-inobata kuchenesa kune mold, kuve nechokwadi chekuchengetedzwa kwenzvimbo.Inovimbisa huchokwadi uye inogona kuchenesa sub-micron-level tsvina zvidimbu izvo zvechinyakare nzira dzekuchenesa dzinganetsa kubvisa.Izvi zvinowana kusvibiswa kwechokwadi-kusina kusvibiswa, kunoshanda, uye kuchenesa kwemhando yepamusoro.

2: Precision Instrument Indasitiri

Mumaindasitiri emakanika echaiyo, zvinhu zvinowanzoda kuve nema esters uye mamineral oiri anoshandiswa pakuzora uye nekuonda kuramba abviswa.Nzira dzemakemikari dzinowanzoshandiswa pakuchenesa, asi dzinowanzosiya zvisaririra.Laser kuchenesa kunogona kubvisa zvachose esters uye mineral oiri pasina kukuvadza pamusoro pezvikamu.Laser-induced explosions ye oxide layers pachikamu chechikamu chinokonzera kuvhunduka kwemafungu, zvichiita kuti kubviswa kwezvinosvibisa pasina mechanical interaction.

3: Rail Indasitiri

Parizvino, kuchenesa njanji pamberi pewelding kunonyanya kushandisa mavhiri kugaya uye jecha, zvichitungamira kukuvadzwa kwakanyanya kwe substrate uye kusara kunetseka.Uyezve, inopedza huwandu hwakawanda hwezvinhu zvinopisa zvinopisa, zvichikonzera kudhura kwakanyanya uye kusvibiswa kwakakomba kweguruva.Laser yekuchenesa inogona kupa yemhando yepamusoro, inoshanda, uye ine hushamwari yekuchenesa nzira yekugadzira yakakwirira-inomhanya njanji muChina.Inogadzirisa nyaya dzakaita semaburi enjanji asina musono, grey spots, uye hurema hwewelding, kuwedzera kugadzikana uye kuchengetedzeka kwekushanda kwechitima chinomhanya.

4: Indasitiri yeAviation

Nzvimbo dzendege dzinoda kupendwazve pashure penguva yakati, asi isati yapendwa, pendi yekare inofanira kubviswa zvachose.Kunyudzwa kwemakemikari/kupukuta inzira huru yekubvisa pendi muchikamu chendege, ichikonzera kuraswa kwemakemikari kwakakura uye kusakwanisa kuwana kubviswa kwependi yenzvimbo kuti igadziriswe.Laser yekuchenesa inogona kuwana yemhando yepamusoro kubviswa kwependi kubva paganda rendege uye inochinjika nyore kune otomatiki kugadzirwa.Parizvino, tekinoroji iyi yakatanga kushandiswa mukuchengetwa kwemamwe mhando dzendege dzepamusoro kune dzimwe nyika.

5: Maritime Indasitiri

Kucheneswa kusati kwagadzirwa muindasitiri yemugungwa kunowanzo shandisa nzira dzejecha, zvichikonzera kusvibiswa kweguruva kwakanyanya kunharaunda yakapoteredza.Sezvo jecha riri kurambidzwa zvishoma nezvishoma, zvakonzera kudzikiswa kwekugadzira kana kuvharika kwemakambani ekuvaka ngarava.Laser yekuchenesa tekinoroji ichapa yakasvibira uye isina kusvibiswa-isina yekuchenesa mhinduro yeinopesana nekuodza coating yenzvimbo dzengarava.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Nguva yekutumira: Jan-16-2024